Get the Grip on Green #3 – Sustainable materials

Recycled Materials

In this new edition, we’re looking at one of the main pillars of sustainability which is of course the material used to produce packaging. As you will discover, some of the common ideas about green packaging might be challenged here. And if you’d like to know more about this topic, just send us an email …

The use of recycled materials is only possible, if we enable recycling through designing our packaging fit for recycling. This is currently not always possible, but we are looking for solutions to reach it. Recycled plastics can be made out of two sources:

– post-industrial / pre-consumer material from productional/ industrial waste (PIR), which is mostly not contaminated,

– post-consumer waste (PCR), which is the waste from our households, and is contaminated with food residues and other materials. But it can also come from deposit systems, which are not contaminated by other materials and the food residues can be cleaned easily.

rPET, rHDPE and rPP are available from these sources.

PIR is a high-qualitiy material and is often reused in related processes of the industry which produce it. This material is not ending up in the recycling system of the household waste. Some governments accept these PIR as recycled plastics for packaging (UK), some do not (DE). Depending on the source, the plastics can be certified for food contact or not.

Recycled PET – rPET

Currently, the only food-grade material approved by EFSA (European Food Safety Authority) from PCR is from PET bottle deposit systems e.g. in the Netherlands, Germany. The reason, why EFSA is certifying this PET as food-grade is, because the deposit systems don’t have a lot of contaminations by residues and are only contain food packaging. Because of this “closed” loop of PET food-grade material, the EFSA approved several recycling processes of this material to produce food-grade recycled PET.

The certified food-grade rPET is used to produce food packaging like Petpackers, which are not part of the deposit system anymore. The closed deposit-loop usually produces PET bottles over and over again from circulating PET material. This is a very efficient system with minimal material loss, and every material which will be taken out, needs to be replaced by virgin PET.

That means to produce food packaging from this rPET e.g. Petpackers, which will end up in the household waste, reduces the amount of bottle-to-bottle PET and the efficiency of the deposit system.

That’s why we agree in the fact that taking rPET out of this loop to use it in products and finally lose the material in the household waste, is not sustainable. To think about how to use the recycled rPET from this source is therefore necessary. A possibiliy is to use it only in clear Petpackers with PP or PE closure and a fitting label, to enable the recyclability. Even if the material won’t come back to a food packaging, it can be reused for non-food applications.

Recycled HDPE – rHDPE & rPP

The EFSA didn’t approve recycled HDPE or recycled PP materials as food-grade, because they usually end up in our household waste and are contaminated. To change this, there are some innovations developed, but not yet implemented: The aim is to improve the sorting during the recycling process to be able to separate food from non-food packaging. This would enable producing more recycled PCR-plastics with food-grade.

One example are digital watermarks, which are invisible for the human eye, but detectable by cameras. These digital marks could be detected during the recycling process and the seperation would follow.

But these developments still need time to be realised. As soon as this will happen, we will include them to our portfolio of sustainable materials.

The quality and properties of recycled materials are similar to virgin material. But because it’s a mix of different qualities and already treated mechanically, it might be less flexible, darker and some other properties can be slightly different. But before it is used for our packaging, the suppliers and we make tests to approve the material and occurred product for its use. These tests cover physiochemical behaviour like migration tests. But also product properties like colour & shape accuracy, load, filling, labelling, sealing, capping, sleeving, packing, shipping.

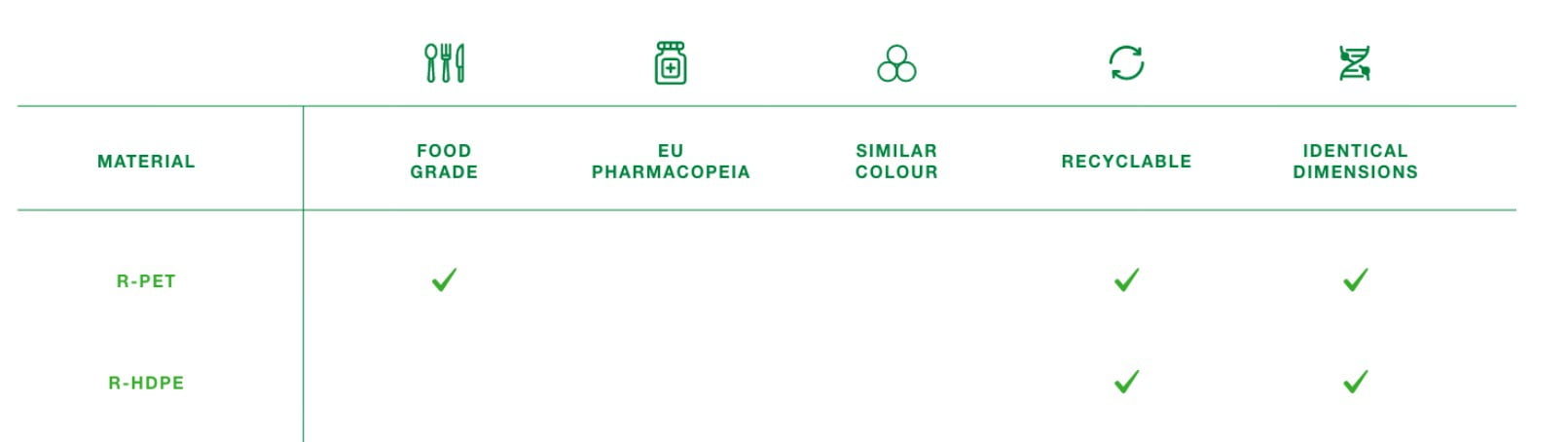

In the following table, you can see the differences between recycled and virgin PET/ HDPE. The virgin versions meet all of the criteria.

Due to the rapid evolution of the sustainability into the packaging sector as well as local differences of recycling processes and law, information provided within this document are for information only.

We advise you to check your local regulation’s update.